The average OEM 63mm downpipe diameter coupled with a restrictive catalytic converter and varying angles don’t allow for ideal flow specifications and result in higher back pressure at the turbo forcing it to work harder and generate excessive heat.

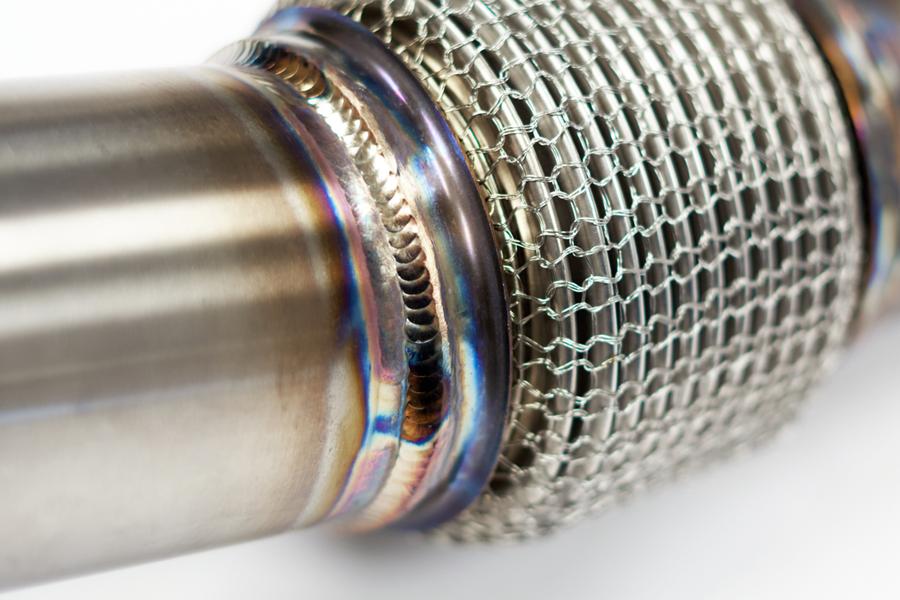

HPA’s resulting 3” downpipe is a fabrication assembly designed around functionality and durability and proudly manufactured in Canada. .063wall T304L stainless mandrel tubing is precision tig welded and Argon back purged for an ultra clean look on the exterior and a perfect clean weld on the interior. Our CNC formed hanger and laser cut flanges mate this assembly to the chassis and will withstand the thermal conditions the turbo will generate. Our flex couplings feature an internal stainless steel interlock liner that facilitates smooth flow of high temperature exhaust gases.

HPA EA888 Gen 1 and 2 street downpipes come standard with our 300C high flow cats while the new MQB GTI and Golf R come standard with our 300 cell metal cat, the same quality of cats used on all HPA twin turbo high performance vehicles.

Features:

- Designed and assembled in-house

- 76mm Diameter

- T304L Stainless Steel

- Full stainless steel construction

- 300 Cell High Flow metal Catalytic Converter

- Reducer to allow for OEM catback

- Argon back-purged TIG Welds

- Lower CNC cut and formed lower hanger bracket

- Interlocking low profile Flex joint for stability under high EGT

- Removed the Factory Catalytic Converter directly off the turbo for increase in exhaust flow and drop in back pressure.

- O2 harness extension

- Precision Stainless V-band turbo flange

- Precision stainless Band clamp to mid pipe

- Integrated Laser Cut / CNC formed heat shield

- Integrated OEM upper turbo support bracket

Reviews

There are no reviews yet.